| Hollis |

Hollis |

89914538776 |

nemapasyuk@gazeta.pl |

Watch YouTube Short

Watch YouTube Short

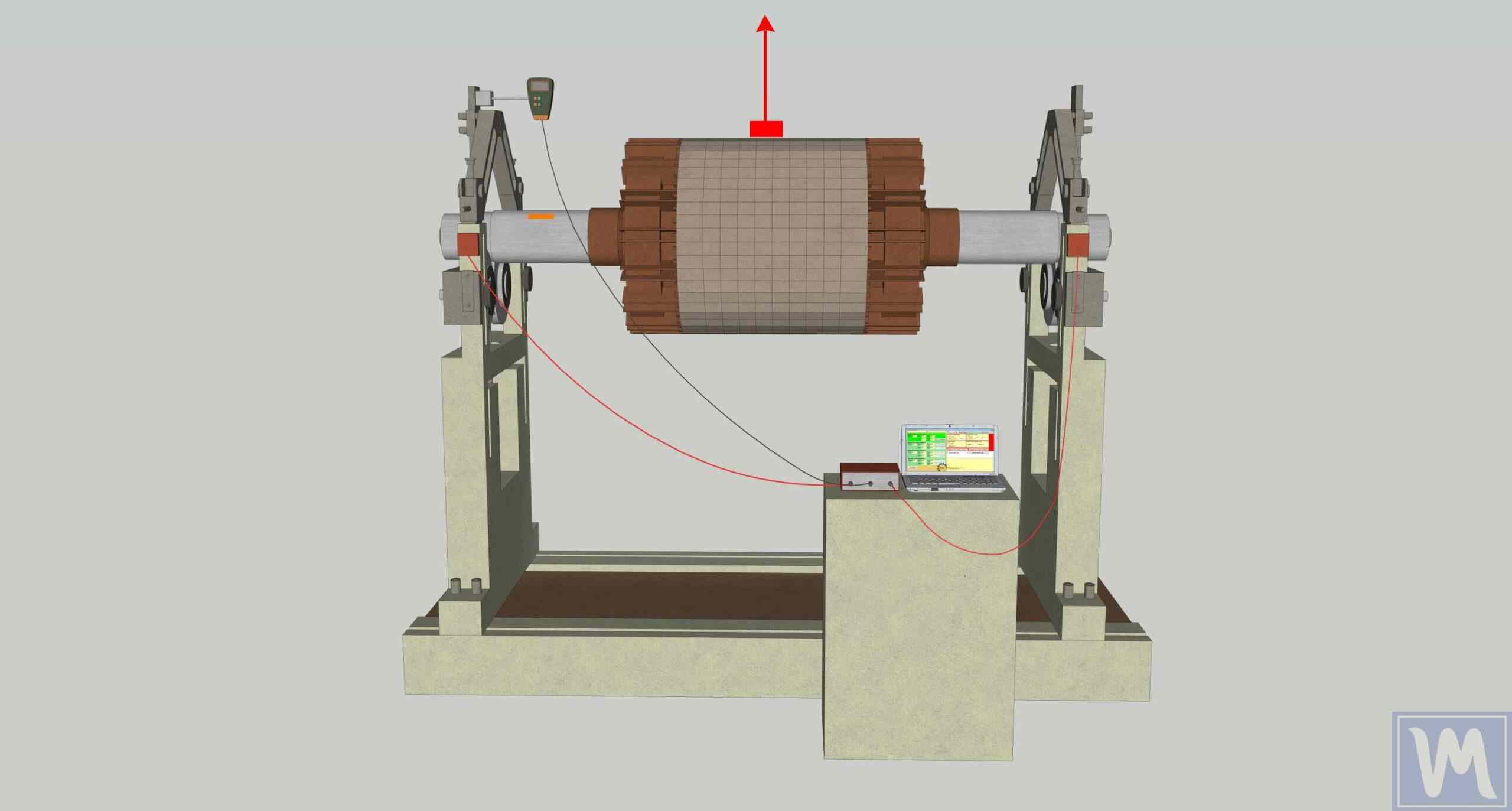

Balanset-1A: Advanced Instrument for Auger Balancing of Rotors

The Balanset-1A stands out as a premier device designed for the precise balancing of rotors, offering both single and dual-plane correction capabilities. This versatility makes it an essential tool for industries where rotor performance and longevity are critical.

Understanding Auger Balancing with Balanset-1A

Auger Balancing refers to the meticulous process of ensuring that rotors operate smoothly without excessive vibrations or imbalances that can lead to premature wear or failure. The Balanset-1A excels in this domain by accommodating the unique structural features of various rotors, determining the optimal number of balancing planes required.

Single-Plane Balancing: Precision for Narrow Rotors

Single-plane, or static balancing, is typically employed for narrow, disc-like rotors that do not exhibit significant axial runout. The Balanset-1A efficiently handles these types of rotors, ensuring stability and reducing the risk of operational issues. Common examples of rotors suited for single-plane balancing include:

- Narrow grinding wheels

- V-belt pulleys

- Disc flywheels

- Gear wheels

- Couplings

- Clamp chucks for lathes

- Narrow fans

Dual-Plane Balancing: Dynamic Solutions for Long Rotors

For longer, shaft-like rotors that require two-plane balancing, the Balanset-1A provides dynamic balancing solutions. This method is essential for rotors that are prone to complex vibration patterns due to their length and the nature of their support structures. Typical rotors benefiting from dual-plane Auger Balancing include:

- Electric motor and generator rotors

- Compressor and pump rotors

- Working wheels of turbines and fans

- Wide grinding discs

- Spindles

- Milling machine shafts with millstones

Key Features of Balanset-1A

- Versatile Balancing Modes: Supports both single and dual-plane Balancing, adapting to various rotor types.

- Precision Measurement: Utilizes advanced sensors and software to detect even minor imbalances.

- User-Friendly Interface: Designed with an intuitive control panel, making the balancing process straightforward.

- Durable Construction: Built to withstand the demanding environments of industrial settings.

- Efficiency: Reduces rotor downtime by providing quick and accurate balancing results.

Benefits of Using Balanset-1A for Auger Balancing

Implementing the Balanset-1A in your maintenance routine offers numerous advantages:

- Enhanced Rotor Performance: Proper balancing ensures smoother operation and extends the lifespan of rotors.

- Reduced Maintenance Costs: Minimizes wear and tear, lowering the frequency and cost of repairs.

- Increased Safety: Balanced rotors are less likely to fail catastrophically, ensuring a safer working environment.

- Optimized Efficiency: Reduces energy consumption by ensuring that machinery operates at peak efficiency.

Conclusion

The Balanset-1A is a state-of-the-art instrument tailored for Auger Balancing of a wide range of rotors. Its ability to perform both single and dual-plane balancing makes it an indispensable tool for industries seeking to enhance rotor performance, ensure operational safety, and reduce maintenance costs. Investing in the Balanset-1A means committing to quality, precision, and reliability in rotor balancing.

Contact Information:

For more information about our Balanset balancing devices and other products, please visit our website: https://vibromera.eu.

Subscribe to our YouTube channel, where you will find instructional videos and examples of completed work: https://www.youtube.com/@vibromera.

Stay updated with our latest news and promotions on Instagram, where we also showcase examples of our work: https://www.instagram.com/vibromera_ou/.

Buy Balanset-1A on eBay

Balanset-1A OEM on Machinio

|